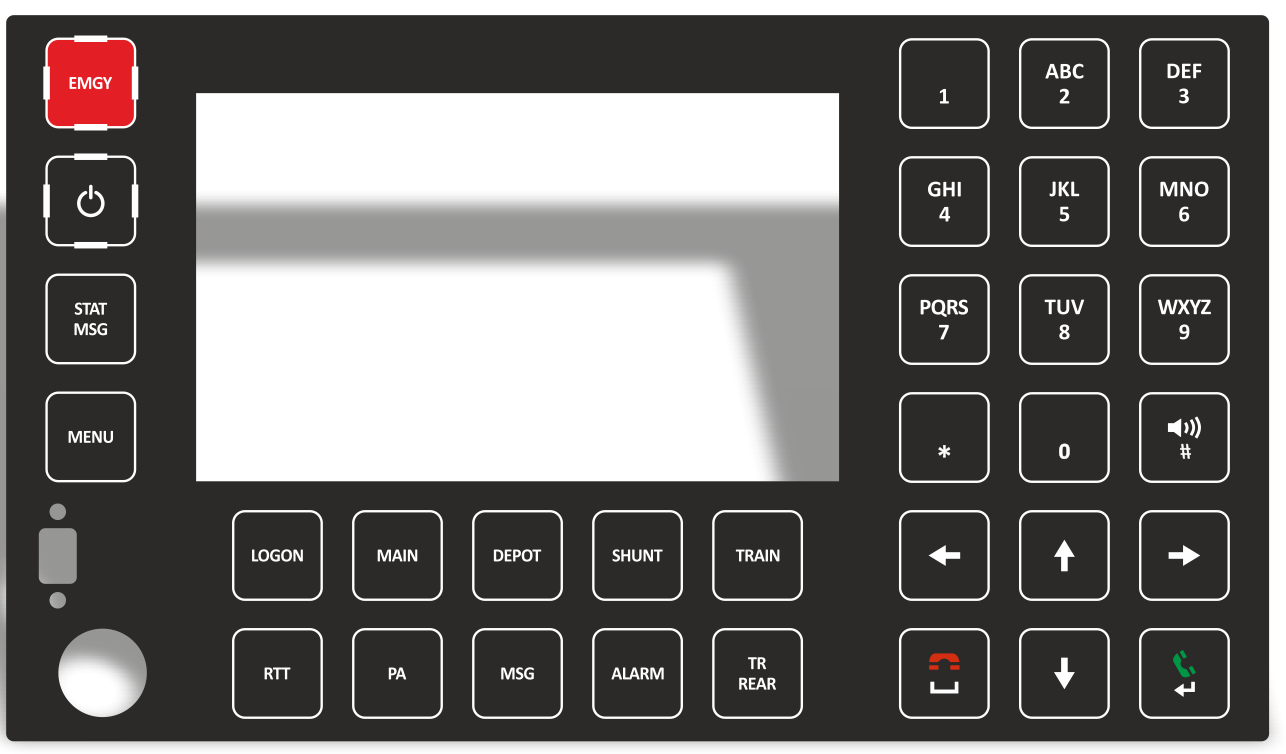

Membrane Keypads works by electrical contact between the keyboard surface and the underlying circuits when key are top areas pressed. These keypad are quite inexpensive resistant against the dirt and liquids than most other keyboards. Membrane keypads easy to clean ,Versatile and flexible. Also membrane keypad can be made moisture proof by using 3M VHB Tapes. Construction of membrane keypads consist of deferent layers like graphic overlay. Graphic adhesive, top circuit, spacer adhesive, metal domes , bottom circuit, back adhesive, also having tails one or more than one with or without connector of 2.54 mm or 1.00 mm pitch. In membrane keypad graphic overlay finishings are available like matt, glossy, textured fine or selective area textured. Constraction of rigid PCB based membrane keypad has different layers like Graphic overlay (Sticker), graphic adhesive dome spacer retainer, adhesive, metal dome PCB with nickle plated gold plated or tin plated.

A capacitive membrane touch switch is a type of switch which operates only when the user makes contact with the object. The capacitive membrane switch uses sensing technology to operate the function of switch when touched.

Capacitive switches use the human body’s capacitance to identify touch and open/ close the circuits. It requires only one electrode to operate, which is found behind a panel of non conductive material like glass, plastic or acrylic etc.

Layers in capacitive touch membrane keypad are as graphic overday, graphic abhesive light guided panel PCB , rear adhesive.

Life of membrane keypad approx – 1 million operations/ operatingvaltage, 35v DC/ temperature – 20- 700 C/ dome – stainless steel in deferent sizes normal tail size -85mm or as per requirements .

Safety label are use to protect from fatal injuries or accidents

Material use and safety labels

Vinyl film with UV coated

Lexan make polycarbonate film

Coted polyster film

White polyster film with UV coated ,Back adhesive for outdoor & indoor ,etc.